Navigating the world of scaffold safety can feel like walking a tightrope. But don’t worry, you’re not alone. In this comprehensive guide, we’ll unravel the complexities for you. We’ll identify common hazards, highlight essential safety equipment, and outline inspection procedures. You’ll learn effective strategies to prevent accidents and understand the legal aspects involved. So let’s dive in because when it comes to your safety on scaffolds, there’s no room for compromise.

Understanding the Basics of Scaffold Safety

Before we dive deeper, let’s start with understanding the basics of scaffold safety to avoid common hazards. First off, you should know your scaffold materials. The material used in constructing scaffolds can significantly influence their stability and durability. Common materials include wood, metal, and synthetic materials such as fiberglass. Each has its strengths and weaknesses: while metal scaffolds are robust and durable, they’re heavy; wooden ones are lighter but less sturdy; synthetic materials offer a balance between weight and strength.

Another critical aspect is load calculations. You’ve got to be aware of the maximum load your scaffold can safely support. This includes not just the weight of workers and equipment on it but also environmental factors like wind load. Neglecting load calculations could lead to catastrophic accidents due to overload.

Remember that safety isn’t optional – it’s mandatory! To ensure that the scaffold is correctly set up following the manufacturer’s guidelines before use. Regular inspections are vital too for identifying potential issues early on.

Identifying Common Risks and Hazards in Scaffold Use

You’re likely to encounter numerous risks when using these elevated structures, so you must understand how to identify them. The most common hazards include falls, scaffold collapse, being struck by falling objects, and electrocution. Understanding these risks allows for effective risk mitigation and hazard communication. This list will really show you why scaffold safety is important.

Let’s delve into each one:

1. Falls: Often caused by a lack of guardrails, non-existent fall arrest systems, or unstable working surfaces. Always ensure safety equipment is in place before starting work.

2. Scaffold Collapse: This can occur due to overloading or improper assembly. Never exceed the recommended weight limit and always follow the manufacturer’s instructions during assembly.

3. Struck by Falling Objects: Tools or materials can fall from scaffolds injuring people below. Implement netting, toe boards, or other protective measures to prevent this.

4. Electrocution: Working near power lines poses a significant risk of electrocution. Maintain a safe distance and use non-conductive tools whenever possible.

Essential Scaffold Safety Equipment

You must equip yourself with the right gear when working on elevated structures. Your safety should be a priority and paramount to this is understanding scaffold anchorage and fall arrest systems.

A scaffold anchorage or tie-off point is an integral part of any scaffolding setup, providing stability and strength. You must ensure its secure fixing to a sound structure capable of supporting at least four times the intended load without failure. A weak or improper anchorage can lead to catastrophic outcomes like tilting or collapsing of the entire scaffold structure.

Fall arrest systems are life-saving devices designed to stop falls in progress, absorbing the force generated during a fall. It usually includes a full-body harness, lanyard, connector, and anchor point. Remember it’s not enough just to own these; they need proper usage too. Ensure your harness fits well. Attach your lanyard directly to an approved anchor point or lifeline.

Scaffold safety doesn’t end here though; regular inspections and maintenance are key as well. By donning suitable gear and mastering how to use it correctly, you’re taking important steps toward ensuring your safety while working at heights.

Proper Procedures for Scaffold Safety Inspection

When it comes to ensuring scaffold safety, your inspection procedures are key. You’ll need to understand the criteria for pre-use inspections, the essentials of routine checks, and the best practices for post-incident evaluations. Each aspect is critical in maintaining a safe working environment and minimizing the risks associated with scaffold use.

Pre-Use Inspection Criteria

Before you climb up, ensure all components of the scaffold meet the pre-use inspection criteria. This process involves meticulous Inspection Documentation and effective Hazard Communication.

1. Inspection Documentation: Record every detail of your scaffold’s condition before use. It’s not just about ticking boxes; it’s an essential part of maintaining safety standards.

2. Hazard Communication: Communicate any identified hazards or issues with the scaffolding to all team members.

3. Condition Check: Assess the structural integrity, stability, and overall safety of the scaffolding before use.

4. Safety Equipment Verification: Verify that all necessary safety equipment is present and in good working order.

Routine Inspection Essentials

Routine inspections aren’t just about maintaining the equipment; they’re essential for identifying potential issues early. You need to understand that these inspections are a critical part of your safety protocols. If you identify these issues, you can ensure scaffold safety by preventing a harmful incident before it even happens.

Inspection documentation is paramount in this process. It’s not only about ticking off boxes on a checklist but also providing detailed descriptions of any irregularities or potential hazards you’ve spotted during the inspection.

Maintenance protocols should be strictly followed after each inspection. If there’s an identified issue, it needs immediate attention and rectification as per the set guidelines. Remember, cutting corners here could lead to severe consequences later on.

Hence, ensuring your routine inspection essentials are well-established can significantly contribute to maintaining scaffold safety at all times.

Post-Incident Inspection Practices

Post-incident inspections are crucial as they’re designed to uncover what went wrong and how to prevent it from happening again. Don’t underestimate the importance of these inspections; they’re a key part of your scaffold safety protocol. Your incident documentation must be thorough, accurate, and promptly compiled for effective emergency response.

To ensure you’re doing it right:

1. Analyze all damaged components closely.

2. Record every detail – no matter how minor it seems.

3. Identify possible causes and preventive measures.

4. Update safety guidelines based on your findings.

This systematic approach allows you to learn from each incident, enhancing overall scaffolding safety while minimizing future risks. Remember – thorough post-incident inspection practices can make the difference between a safe work environment and repeated accidents!

Effective Strategies to Prevent Scaffold Accidents

In your quest to prevent scaffold accidents, you’ll find that regular safety inspections are a critical foundation. They’re not all you need, though – proper training programs equip your team with the necessary knowledge and skills to safely navigate scaffolding work environments. Lastly, don’t underestimate the value of utilizing protective equipment; it’s a vital frontline defense for workers high above ground level.

Regular Scaffold Safety Inspections

You’re responsible for conducting regular safety inspections to avoid common scaffolding hazards. This task isn’t just about ticking boxes; it’s about ensuring comprehensive adherence to safety protocols and meticulous inspection documentation.

Here’s how you can achieve this:

1. Documentation: Keep records of every inspection, noting any discrepancies or issues found.

2. Safety Protocols: Follow established procedures diligently, and don’t cut corners.

3. Training: Ensure those using the scaffold are well-trained in its safe operation.

4. Communication: Report any unsafe conditions promptly and clearly.

Proper Training Programs

Proper training programs are crucial, as they’ll equip your team with the necessary skills and understanding to perform their tasks effectively. Focused on scaffold safety, these programs should utilize quality safety training resources to ensure comprehensive knowledge transfer.

As a leader, you have the responsibility of implementing a training effectiveness evaluation. This will help determine if your team truly grasps the core principles of safe scaffolding use and handling. Monitor their progress and provide continuous feedback for improvement.

Utilizing Protective Equipment

Utilizing protective equipment is crucial, as it will significantly reduce the risk of accidents and injuries on the job site. It’s not just about having the right gear, but also ensuring regular equipment maintenance and appropriate worker’s attire.

Here are four key points for your safety:

1. Always wear a hard hat to protect against falling objects.

2. Use harnesses when working at heights, it could save your life in case of a fall.

3. Invest in high-quality work boots with slip-resistant soles to prevent slips and falls.

4. Don’t neglect gloves, they protect against cuts and abrasions.

Legal and Regulatory Aspects of Scaffold Safety

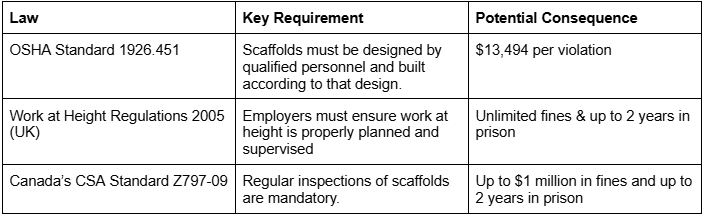

Understanding the legal and regulatory aspects of scaffold safety isn’t just about compliance, it’s crucial for your team’s well-being on the job site. You’re expected to not only know but also adhere to safety legislation. Compliance consequences are severe, they range from fines, and project delays to even imprisonment.

Here is a summary of key scaffold safety regulations:

Non-compliance doesn’t just result in penalties; it puts lives at risk. So keep abreast with current regulations because ignorance isn’t an excuse in law. Prioritize your team’s safety by fully understanding these laws and implementing necessary measures.

Frequently Asked Questions

What Type of Training Is Needed for Workers to Safely Use Scaffolds?

You’ll need training in Scaffold Inspection Protocols and the use of Personal Protective Equipment. It’s crucial to understand how to inspect, assemble, and disassemble scaffolds, and properly utilize safety gear for maximum protection.

What Are Some Emergency Procedures to Follow in Case of a Scaffold-Related Accident?

In case of a scaffold-related accident, you’ll need to clear the area, initiate emergency communication, provide first aid if trained, and report the accident immediately. You must follow all company safety protocols.

How Often Should Safety Drills Be Conducted for Workers Using Scaffolds?

You should conduct safety drills and equipment inspections for scaffold users at least once a month. You must be consistent in maintaining drill frequency to ensure workers are always prepared for potential hazards. This is important because while taking scaffold safety into consideration, inspections not happening could lead to very dangerous situations.

What Are Some Additional Precautions to Take To Maximize Scaffold Safety in Adverse Weather Conditions?

In adverse weather, you should use weatherproof materials for scaffolding. Also, don’t neglect the usage of protective gear. It’s crucial to ensure stability and prevent slips or falls due to wet or icy conditions.

Are There Any Specific Insurance Policies Needed When Working With Scaffolding on a Construction Site?

Yes, you’ll need specific insurance for scaffolding work. This includes liability insurance which covers scaffold-related accidents. The policy coverage details and scaffold insurance costs can vary, so it’s essential to shop around.

SEO done by datafanatics.com

To find more information related to construction safety, click here to view our blog posts!