You’re walking a tightrope if you’re considering Crocs for your industrial job. Sure, they’re comfortable, but are they OSHA-approved? As we dive into the nitty-gritty of safety regulations, you’ll discover where Crocs stand in comparison to other work footwear and learn about potential hazards. Don’t be caught flat-footed; let’s figure out if these popular shoes meet the cut in an industrial setting.

Understanding OSHA Standards for Footwear

Let’s delve into understanding OSHA’s footwear standards, which will help us determine if Crocs are approved. You see, OSHA (Occupational Safety and Health Administration) is all about ensuring workers’ safety. They’ve set up certain regulations for footwear to reduce the risk of workplace injuries.

The crux of OSHA compliance lies in regular Footwear Inspections. These are crucial to ascertain if a shoe meets the required criteria. It’s not about style or comfort alone; your footwear must provide adequate protection against potential hazards at your workplace.

OSHA doesn’t specifically approve or disapprove brands like Crocs. Rather, they outline general guidelines that all work shoes should follow. For instance, you need foot protection if there’s a risk of foot injuries from falling or rolling objects, objects piercing the sole, or exposure to electrical hazards.

Evaluation of Crocs in Industrial Settings

In industrial settings, you’re probably wondering if these popular rubber clogs meet safety standards. You’re right to be concerned. Let’s dive into the specifics of Croc’s durability and comfortability in an environment where safety is paramount.

– Crocs Durability:

– These clogs are known for being long-lasting, but industrial settings pose different challenges. Sharp objects, hot surfaces, or heavy equipment can damage them.

– The fact that they aren’t puncture-resistant or fireproof may make you think twice about their suitability in your workplace.

– Crocs Comfortability:

– There’s no denying the comfort level of Crocs. They’re lightweight and provide excellent cushioning which is a boon during long shifts.

– However, comfort should never compromise safety. Their lack of protective toe caps and slip resistance is concerning.

Facts on hand, it’s clear that while Crocks score high in durability and comfort for everyday wear, they might fall short of meeting OSHA standards in industrial environments. Always remember that the right footwear can protect you from various hazards at your workplace thereby saving potential medical costs and most importantly – keeping you safe! Make sure to choose wisely!

Comparison of Crocs to Other OSHA-Approved Footwear

Comparing these popular clogs to other safety-compliant footwear, it’s evident they may not be the best choice for industrial settings. While Croc’s comfortability and lightweight design make them a favorite among many, their suitability in an environment requiring OSHA-approved footwear is questionable.

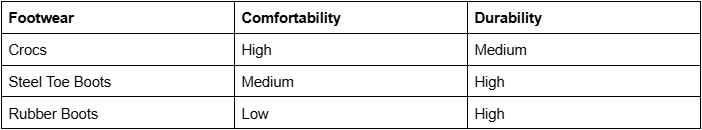

Below you’ll find a comparison table that provides further clarity.

While Crocs excel in comfortability, their durability doesn’t match up to the standard of steel-toe boots or rubber boots which are typically used in industrial environments.

It’s crucial to understand that OSHA regulations prioritize safety over comfort. Though Crocs might seem attractive due to their ease of wear and cushiony feel, they lack protective features like puncture-resistant soles and toe protection which are mandatory in hazardous workplaces.

Therefore, although you might appreciate your Crocs’ comfortability and moderate durability for everyday use, they aren’t as advisable as PPE (Personal Protective Equipment) where robustness against potential hazards is paramount. Your safety should always come first!

Potential Hazards of Wearing Crocs at the Workplace

You might not realize it, but wearing those comfy clogs at work could expose you to certain hazards. Despite the Croc’s comfortability, they may not be the best choice for all workplace environments.

Consider these potential dangers:

– Lack of Protection: Crocs aren’t designed to safeguard your feet against heavy objects or sharp tools.

– Imagine dropping a weighty box on your foot and having only a thin layer of foam between you and a painful injury.

– Picture stepping on a sharp object with no protective sole to save you from a puncture wound.

– Risk of Workplace Slips: The soles can become slippery on wet or oily surfaces.

– Envision slipping in front of your colleagues during an important meeting due to slick floors.

– Think about losing control while carrying precious cargo, leading to spills, damage or even accidents.

– Inadequate Support: Extended wear could lead to foot pain and posture problems.

– Visualize going home after a long day’s work with throbbing feet because your shoes didn’t provide adequate support.

Case Studies: Incidents Involving Crocs at Workplaces

Let’s delve into some real-life incidents where people wearing those foam clogs at the workplace faced unexpected mishaps. Despite Crocs’ popularity, their use in certain work environments resulted in accidents that could’ve been avoided with appropriate footwear.

Take the case of a restaurant worker who slipped while carrying a tray full of dishes, leading to minor injuries and damaged property. His Crocs failed to provide the necessary traction on the wet floor, a risk often overlooked by many due to their comfort appeal.

Then there’s the incident involving an assembly line employee. The open design of her Crocs allowed a piece of machinery to crush her toe, causing significant injury. Had she worn closed-toe safety shoes as required by OSHA regulations, this accident might not have occurred.

Workplace accidents like these underline why you must adhere strictly to safety standards when selecting your footwear for work. Remember that while Crocs may seem convenient and comfortable for daily wear, they’re not designed or approved for every workplace setting. Always prioritize safety over style; it can save you from potential harm and trouble down the line.

Frequently Asked Questions

What Materials Are Typically Used in the Manufacturing of Crocs?

Crocs are typically made from a material called Croslite, a proprietary closed-cell resin. It’s what gives Crocs their unique lightweight, non-marking, and odor-resistant features, aligning with Crocs’ sustainability practices.

How Do Croc Prices Compare to Other OSHA-Approved Footwear Brands?

When comparing Crocs’ affordability to other footwear brands, you’ll find they’re typically more budget-friendly. However, it’s critical to consider that not all cheaper shoes meet OSHA standards for workplace safety.

Are There Any Specific Industries That Recommend or Discourage the Use of Crocs?

While you might appreciate Crocs’ versatility and comfort, certain industries, like manufacturing or construction, generally discourage their use due to safety regulations. However, some healthcare settings may recommend them for employee preferences and ease of cleaning.

What Is the Typical Lifespan of a Pair of Crocs When Used in an Industrial Setting?

Typically, Crocs’ durability in industrial usage varies. It’s heavily dependent on the nature of your work and frequency of use. They might last a few months to a year, but they aren’t designed for such environments.

How Does the Comfort Level of Wearing Crocs Compare to Other Types of Work Shoes?

Croc’s design evolution prioritizes comfort over most work shoes. They’re like walking on clouds, your feet cradled in soft foam. The health benefits include reduced foot fatigue and pain, making long shifts more bearable for you.

SEO done by datafanatics.com

To find more information related to construction safety, click here to view our blog list!